Full Description

General Ventilation Systems

Industrial workplaces, such as manufacturing plants, fabrication workshops, production facilities, laboratories and fabrication workshops are subject to industrial processes where dust, fumes, heat and gases are given off.

Having primary local exhaust ventilation systems (LEV) to capture these elements at source is always recommended as the best method to remove these from worker's breathing zones. However, residual fumes and gases can often rise above the capture zone of the LEV system and disperse into the broader working environment.

By providing secondary extraction ventilation systems to remove residual fumes and gases can improve the indoor air quality by providing more frequent air changes and providing the workplace with fresh, clean air. Airborne contaminants must be collected and treated before being discharged from the building or before being recirculated.

How do General Ventilation Systems Work?

A main feature of the general ventilation systems captures residual, warm fumes and gases that are emitted from the process and have risen vertically towards the roof, which haven't been caught and directly removed at-source. The general ventilation system continuously removes polluted air that settles just below the roof, roughly two or three metres below. An additional benefit of this system is that it still allows for any vehicles or gantry cranes to operate within the building.

By installing a high-level general fume extraction system not only creates a cleaner, safer work environment for all staff in the business but also provides cost savings; rather than trying to extract the entire volume of the building we target the dirty band of fume that can be visibly seen with multiple extraction points.

Go Green with General Ventilation

Manufacturing businesses are required to use vast quantities of energy, in both the manufacturing process and maintaining the facility's environmental conditions, however, energy can be saved by proper use of insulation and ventilation, and by recovery of waste heat. Ventilation equipment can be equipped with energy-saving and energy-efficient technologies not only to remove contaminants from the air but also to provide fresh air throughout.

Residual Welding Fume

When welding, capturing harmful substances given off from the welding process at sources is the best and most effective method to capture and remove fumes, however, there's several instances or situations where this may not always be possible to capture all the fume given off, for example, whilst welding on a large workpiece - the on torch welding gun, or extraction arm may not capture all the fume, whilst changing welding positions or where workpieces are widely spread that the welding fume extraction system may not reach.

By providing a secondary, general ventilation welding fume ventilation system, you'll be able to extract welding fumes via a ducting system, typically located above a gantry crane track.

What do the HSE State?

In HSE’s WL3: Welding Fume Control guidance, it states that: “Effective general ventilation provides rapid fume clearance as is necessary to minimise the fume build-up from over the shift where welding fume is not fully removed by local exhaust ventilation (LEV). Mechanical general ventilation is typically required because natural ventilation (from through draughts) is not sufficient enough to disperse the fume generated.”

On HSE's 'Ventilation' webpage also state: "Sometimes planned, powered general ventilation is an integral part of a set of control measures, eg the welding of large fabrications in a workshop."

Find out more about Welding Fume Extraction page.

The Right General Ventilation Solution for Your Needs

Auto Extract Systems can help specify and design the right LEV system for your business's requirements. We only use the highest quality products and installations come complete with a 12-month installation warranty. Find out more about our LEV Installations service.

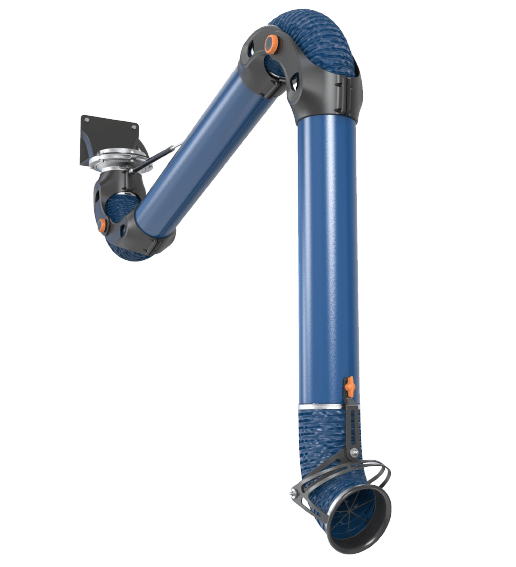

We always recommend extraction at-source, find out about our capture philosophy here. However, to provide additional general ventilation, as a secondary measure in workshops, we recommend ‘wrap-around' general ventilation LEV systems.

These wrap around systems typically consist of two runs of ducting, which stretch the length of a workshop and feature a series of louvred grilles. The grilles capture and remove welding fume plumes that have risen and settled in the hot air just below the roofline. This layer of hot dispersed fumes is typically referred to as the ‘dirty band’. The fan then vents captured welding fumes to the atmosphere in accordance with HSG258 guidelines on ‘Controlling Airborne Contaminants at Work: A Guide to Local Exhaust Ventilation (LEV)’ and conform with HSE inspection standards.

A Complete LEV System

General ventilation systems should be utilised in conjunction with one of our centrifugal fans to vent the captured fumes either directly to the atmosphere or depending on the working process, via a filtration unit.

To find out more about general ventilation systems and how we can help you find the right local exhaust ventilation (LEV) system for you and your business, head over to our News section. To arrange a free site assessment, call us on +44 (0)1942 267444 or click the yellow Request My Free Assessment button above.

Learn How We helped Businesses Like Yours

After installing a bespoke and innovating ‘wrap-around’ general ventilation system for a Welsh manufacturer, their maintenance manager found the system was a great resource and success in the height of Summer to draw heat (from manufacturing plant and workstations) out of the building when temperatures had exceeded 30oC. Read the full case study here.

Request your FREE LEV Site Assessment Today!

We'll call to arrange a convenient time and date to visit your site. We'll analyse your working processes, assess the substances used and the contaminants generated. We'll work out how best to control the dust and fume in a way that's in line with your COSHH risk assessment. Next, we'll design you a comprehensive LEV system that adheres to HSG258 guidance and send this you to via email.

We'll do all this to ensure we fully understand your dust and fume extraction requirements and help you to provide a pollution-free workplace!

This is an amazing service we do for thousands of businesses throughout the UK and Ireland every year. We work with such a wide variety of industries, from manufacturing, industrial, woodworking, pharmaceutical and automotive workshops to schools, colleges and military establishments.

Request your FREE, no-obligation LEV site assessment today!

About Us

Auto Extract Systems Ltd is the UK’s leading Local Exhaust Ventilation (LEV) company. Over the last 20 years, we've helped thousands of businesses create dust and fume free workplaces.

As experts in all things LEV, we can help your business become COSHH (Control of Substances Hazardous to Health) Regulation 2002 compliant with a tailored LEV solution. We provide comprehensive design, installation, maintenance and certification services across a range of industry sectors. Find out more about us here.